Hot Water Heating

Water Heating Technologies

Overview

The heating of water is an energy intensive process in a technology that dates back to the second or third practical use of fire (behind ‘space heating’ and cooking). Water is the basis for the definition of a BTU. 1 BTU = the amount of energy it takes to raise 1 pound of water, 1 degree Fahrenheit. Since water weighs about 8.34 lbs/gallon, and we like to use it above 100F, we put a lot of BTUs into our water.

Water heating can be categorized in the following general classes:

- Residential water heaters – tank units typically 30 or 40,000 BTUs/Hour in gas

- Commercial tank water heaters 199,000 BTUs to about 500,000 BTUs/Hour

- Water Heating Boilers (essentially the same as space heating boilers)

- Instantaneous, tank-less, steam convertors

- Direct Contact water heaters (submerged combustion)

- Booster Heaters

- Pool Heaters, snow melt systems and other specialty applications

Residential Water Heaters

In addition to home use, residential water heaters are common in small commercial and industrial office buildings. They are typically 30 or 40 gallons and have BTU ratings that match their size (30,000 BTUs/Hr and 40,000 BTUs/Hr). These units are very low cost and can produce water up to about 150F in volumes of about 20 to 30 gallons per hour.

Water heaters are rated according to their recovery rate, or the number of gallons of hot water they can produce in one hour after their storage tank has been drawn down. This varies with the inlet and outlet water temperatures. The larger the burner, the higher the recovery rate. The larger the storage tank, the more hot water they can provide in the first hour.

Commercial Water Heaters

Commercial basic tank water heaters are simply heartier versions of the residential units. They often have ratings of 199,000 BTUs/hour as many codes change at 200,000 BTUs/hour and above. They have a storage tank of about 100 gallons and can heat water to about 180F. These units are common in small restaurants, small hotels, and large office buildings.

Energy Efficiency

In 2008 ENERGY STAR released the first standards for water heaters at 62% for tank-style heaters and 82% for tankless heaters. That means that older/standard water heaters are less than 60% efficient. These standards are for residential-size heaters. The newest water heater designs are reaching into the +90% range. To get above 90% efficient the water heater must be able to condense the flue gas. Condensing water heaters are available now in commercial equipment and some manufacturers are working on condensing water heaters for smaller commercial and residential applications.

To estimate savings from converting to a higher efficiency water heater, you must first have an estimate of how much you are currently spending to heat water. Then it is a simple matter of applying the improvement in efficiency times the total cost. The fastest way to estimate your hot water cost is to consider your summer time gas bill. Typically summer gas usage is mostly hot water, with only small amounts for cooking and clothes drying. Be sure to subtract the Monthly Service Charges and Taxes to get the true cost of natural gas.

EXAMPLE: We have determined that our average summer gas usage is $50/month. Converting from a 55% old tank heater to an 80% tankless gains 25% in efficiency improvement. $50/month x 25% = $12.50/month in savings or about a $150/year. Not bad, but not the “Hundreds of dollars” that some advertisements may claim!

How They Work – GAS

Venting

New gas water heaters are available with a ‘direct or power vent’ that allows them to be installed in new houses that also have a high-efficiency power vent furnace, or to be retrofitted where there is no flue/chimney. The power-vent water heaters are substantially more expensive to purchase and require electricity to operate. In new construction, some money is saved on a flue, and there are more installation options. They are about the same efficiency as the standard vent units; a small is fan is used to dilute the flue gases to lower the temperature enough to vent them without the need to create a draft. Often, standard PVC (plastic) pipe can be used as a vent.

ALL GAS WATER HEATERS MUST BE VENTED according to manufacturer’s recommendations and local code requirements.

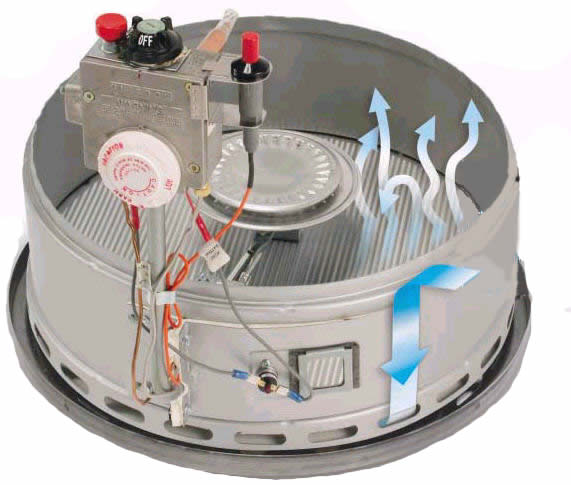

Gas Burner and Controls

Water Piping

Cold water enters the tank at the bottom and hot water is taken off the top. Manufacturers use various methods to stirring the incoming water to help keep sediments from building up on the bottom of the tank.

Heat Transfer

Most of the water heating is accomplished as the heat goes up the vertical tube in the middle of the water heater tank. Manufacturers use various methods and shapes to increase heat transfer from the tube to the water.

Combination Water Heaters and Space Heating Systems

Special water heater systems have been approved for use as combination space heating and water heating systems. They make an inexpensive system for small spaces – such as condos and cabins, and for heating systems in moderate climates. In short, a heavy duty water heater provides hot water to a fan coil unit used for space heating AND domestic hot water at the same time.

For information see Space Heat Water Heat Combo

Continuous Water Heaters

Continuous or Instantaneous water heaters have no storage tank. They heat water on demand. Because there is no storage tank, there are no standby-losses from the tank. Both gas and electric units are available in a limited number of sizes. These units have a substantially higher first cost and do not actually heat the water any cheaper; the savings comes from saving the standby losses – which can be high in certain applications.

For more information about Gas Continuous Water Heaters

More Information

Manufacturers

The following is a short list of major manufacturers with helpful information on their web sites. Some select information has been provided below, along with links for additional information on each product line.

A.O. Smith Water Products Co., Inc

A.O. Smith Water Products Co., Inc

World Headquarters

11270 West Park Place

Milwaukee, WI 53224

Telephone: 414-359-4000

Since its founding in 1936, A.O. Smith Water Products Company has placed a premium on engineering excellence. This has resulted in many “firsts” in both residential and commercial water heaters and boilers. For over 60 years, an ongoing commitment to innovation and continuous product improvement has made A.O. Smith one of the most trusted, most asked for names in water heaters.

Go to the AO Smith web site at www.hotwater.com

American Water Heater Company

American Water Heater Company

500 Princeton Rd.

Johnson City, TN 37601

Telephone: 423-283-8000

American Water Heater Company is one of the world’s largest manufacturers of water heater products. Ask for American’s full line of reliable and efficient products under the PROLine™ brand of residential and light-duty commercial products through your professional plumber or wholesaler. Nothing is more important than protecting your family from injuries. That’s why a gas water heater equipped with a new Flame Guard® Safety System* can be so important. Flame Guard® is the world’s first safety feature to reduce the risk of a flammable vapor-related fire from a gas appliance.

Go to the American web site at www.americanwaterheater.com

Bradford-White

Bradford-White

725 Talamore Dr.

Ambler, PA 19002

Telephone: 215-641-9400

Go to the Bradford-White web site at www.bradfordwhite.com

Bradford-Whites new and greatly expanded web site now also includes a site called ‘Right Spec’ which is a comprehensive site for water heater sizing, spec sheets, piping diagrams, and brand name cross-reference guide. The site may require log-in, but it is instant and free.

To go to the Right-Spec web site rightspec.bradfordwhite.com

Rheem and Ruud

Rheem and Ruud

Rheem is headquartered in New York. Rheem has manufacturing facilities in Montgomery, Alabama; Fort Smith, Arkansas; Milledgeville, Georgia; and Oxnard, California. Rheem has two Canadian locations in Hamilton, Ontario and Mississauga, Ontario, and one Australian location in Mulgrave, Victoria. Rheem also has a manufacturing facility located in Nuevo Laredo, Mexico. All manufacturing facilities are ISO 9000 certified. In 1987, Rheem became a wholly owned subsidiary of Paloma Industries of Nagoya, Japan, the world’s largest producer of gas appliances.

Go to the Rheem web site at www.rheem.com