Heat Pumps

Space Heating – Heat Pumps

Overview

The heat pump is the most energy efficient ELECTRIC heating system available. The heat pump uses a combination of the vapor compression cycle and available ambient heat to move heat from one place to another. Because a heat pump MOVES heat and does not produce heat, it achieves a very high energy efficiency. A heat-pump provides BOTH space heating and cooling. There are also heat-pump water heaters that heat potable water.

It is easy to confuse ‘efficiency’ with operating costs and environmental issues. Although heat pumps are more than 100% efficient, they typically are not less expensive to operate nor or they necessarily better for the environment than natural gas systems. The cost to operate depends on your local climate and energy costs and the environmental impact depends on the source of the electric generation.

Heat pumps are either ‘air’ or ‘water’ source, depending on the heat sink they work with. Water-source heat pumps (geothermal) are either closed-loop or open-loop. Closed-loop systems can either be ‘earth-coupled’ or operate with a boiler and cooling tower.

Conventional heat pumps used for space conditioning are available in sizes from about 1 ton to around 20 tons in a single unit. Heat pumps are rated in EER or SEER (Seasonal Energy Efficiency Rating) in the cooling mode and COP (Coefficient Of Performance) in the heating mode. The higher the SEER or COP, the more efficient the unit.

1 Ton = 12,000 BTUs Moved

(S)EER = (Seasonal) Energy Efficiency Rating, 10+ is good

COP = Coefficient Of Performance, 3.0+ is good

3 COP =~ 10 EER

The Higher the “source” temperature, the more efficient the heat pump operates

How They Work

The basic principal of a heat pump is that heat naturally flows from hot to cold. A refrigerant has a

very low phase-change temperature, meaning it is a gas at a very low temperature. Refrigerant can be a vapor at around 0F. Therefore, even though the ambient air or water maybe only 45F, it is much warmer than the refrigerant. By using a heat exchanger, heat flows from the warmer air or water (the source) and into the cold refrigerant, warming it up.

The refrigerant then flows (suction side) to the compressor, where electric energy is added to compress the gas into a liquid. Basic physics for any gas, is temperature goes up as a gas is compressed. If the gas is compressed into a liquid, a phase-change results in additional energy compression and heating of the liquid. The liquid refrigerant in the condenser coil/heat exchanger is around 110-120F. Heat now flows from the hot refrigerant into the cooler air or water on the other side of the heat exchanger, cooling the refrigerant.

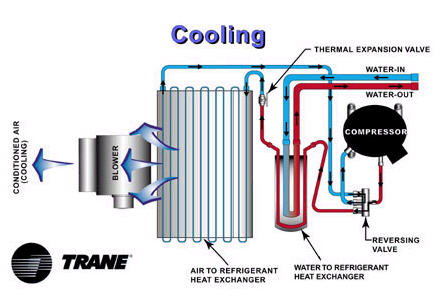

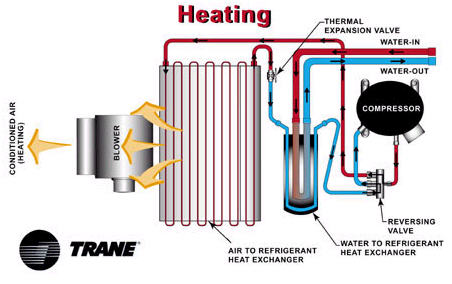

The refrigerant continues in the cycle through a metering valve, called a ‘Thermal Expansion Valve’ in the diagrams below, where it is allowed to quickly expand back into the evaporator coil/heat exchanger. The sudden pressure drop causes a phase-change and a drop in temperature. The refrigerant as a gas is now colder than the source and the cycle repeats.

The heat-exchanger that has compressed/liquid refrigerant is hot (the Condenser); the heat-exchanger that has expanded vapor is cold (the Evaporator). Through the use of a direction-switching valve, which heat-exchanger is hot, and which one is cold, determines whether the heat-pump is in the cooling or heating mode.

In the cooling mode, the hot heat-exchanger is in the ‘source’ (water or outside air) and the cold heat-exchanger is in contact with the air or water being delivered to the conditioned space. Thus, heat is taken from the conditioned space (heat flows INTO the cold coil) and dumped into the source (heat flows OUT of the hot coil) achieving a cooling of the conditioned space.

In the heating mode, the cold heat-exchanger is in the ‘source’ (water or outside air) and the hot heat-exchanger is in contact with the air or water being delivered to the conditioned space. Thus, heat is taken from the source (heat flows INTO the cold coil) and dumped into the conditioned space (heat flows OUT of the hot coil) achieving a heating of the conditioned space.

EER and COPs

Energy Efficiency Ratio or Rating (EER) and Coefficient Of Performance (COP) are unit-less numbers that represent efficiency. The higher the number, the higher the efficiency. EER is used to rate small tonnage air conditioning units, and COP is used to rate heating performance of equipment that use the vapor compression cycle (heat pumps, gas engine-driven chillers, absorption chillers, etc.). Therefore, heat-pumps will generally have both an EER and COP rating.

EER = (Output BTUs) / (Input Watts)

If a 1 Ton unit (12,000 BTUs Cooling Output) has an EER of 10, then the Input Watts must be:

10 EER = (12,000 BTUs) / (1,200 watts)

If the unit is a higher efficiency unit, it would have less input watts to produce the same amount of cooling.

If the EER = 12, then:

12 EER = (12,000 BTUs) / (1,000 watts)

COP = (BTUs Out) / (BTUs In)

If a 1 Ton unit has a COP of 3:

3 COP = (12,000 BTUs Out) / (4,000 BTUs In)

1 watt = 3.413 BTUs so 4,000 BTUs = 1,172 watts

Therefore, 3 COP is about equal to 10 EER

COP can also be thought of in terms of percentage where a COP 1.0 = 100% Efficient and COP 3 = 300% efficient. This is because both Input and Output units are in BTUs.

Application Information

The warmer the source temperature, the higher the efficiency of the heat-pump. With similar source temperatures, air-source and water-source heat-pumps have similar efficiencies. When source temperatures drop below about 45F, efficiency takes a dramatic drop. This is why air-source heat-pumps do not do as well in northern climates, and closed-loops for water-source heat-pumps must be carefully designed.

In the cooling mode, when the outdoor air or loop temperature exceeds about 90F, there is a similar drop in cooling efficiency.

Air Source Heat Pumps

Air Source Heat Pumps

Air-source heat-pumps are used mostly in stand-alone residential and small commercial applications in moderate and southern climates. They resemble air-cooled air conditioning units, but are a little larger for the same tonnage. Air-source heat-pumps seem to have fallen from favor in northern climates, and are not as common as they were in the 1980’s.

Air-source heat-pumps operating in northern climates suffer a substantial efficiency drop below about 40F. Typical stand-alone heat-pumps have electric resistance strip heat installed as a supplement or auxiliary heat. Resistance has a COP = 1.0. A heat-pump has a 2 stage thermostat. If the heat-pump alone is not keeping up with the heating demand, the resistant heat (second stage) is turned on. Depending on the control set-up, the heat-pump may also continue to run, or be shut-off when the resistance heat comes on.

Typical air-source heat-pumps in northern climates have a seasonal COP of about 1.5. In moderate climates, they are about 2.5. The difference is the number of hours the resistance heat runs.

Air-source heat pumps can also be added-onto fossil fuel furnaces. The add-on heat-pump is the same as any other air-source heat-pump, except that the second stage heat is a fossil furnace, rather than electric resistance heat. This is a popular choice in moderate climates. A heat-pump is about twice the cost of a conventional cooling system, but can pay for itself in heating savings (depending on electric versus fossil fuel costs and local climate conditions).

Water Source Heat Pumps

Water-source heat-pumps are used in stand-alone residential applications up through high-rise buildings with hundreds of units on a single loop.

Water-source heat-pumps are used in stand-alone residential applications up through high-rise buildings with hundreds of units on a single loop.

The efficiency of water-source heat-pumps depends on the source water temperature. Open loop systems depend on local water table conditions. Even in northern climates, water-table water stays above 45F, which is warm enough to produce a COP 3 or better. If water is taken from a surface water source, such as a stream or lake, the withdrawal point will be critical to temperature. A local permit will be required to operate an open-loop system in most areas. They may be prohibited in some locations. Fowling of the water system is common with open-loop systems.

Closed-loop earth-coupled systems eliminate most of the problems with open-loop systems, but are substantially more expensive to install. The cost of the loop can easily cost 1 to 3 times the cost of the rest of the system. Depending on available space and installation considerations, either a horizontal or vertical system can be used. Vertical systems tend to be more efficient for the same pipe surface area, due to warmer temperatures at deeper depths. Vertical systems are also more likely to be in contact with ground water, which improves thermal transfer. Both systems will use a mixture of water and antifreeze in northern climates. Although the antifreeze reduces the efficiency of the heat exchange (alcohol has a lower specific gravity than water and therefore will not hold as many BTUs per gallon), it is required to protect the loop.

Vertical systems drill large diameter wells that have both a supply and return line looped in the same well. Flexible poly-pipe is used with either no fittings or fused joints inside the wells. Fittings are generally only made were they can be accessed in the event of leaks. The number of wells required is a function of their total depth, load demand and local soil/ground water conditions.

Horizontal systems need to be buried at least 6 feet deep and require a LOT of area, which is the reason for their high installation costs. Most of the time, vertical systems are selected for commercial installations.

Closed Loop Boiler and Cooling Tower

Closed-loop water-source heat-pumps are used to heat and cool multi-zone commercial buildings, schools/institutions, and living units. Several small heat-pumps are connected to a common source, that is a pipe of water looped through the building. The loop is then either coupled to a ground coil or has a boiler and a cooling tower. With a ground-coupled system, operation is the same as the stand-alone systems, but the ground loop is MUCH bigger. An alternate and more common system, uses a boiler to provide supplemental heat, and a cooling tower to provide cooling to the loop.

Closed-loop systems can work well in buildings that are OFTEN heating and cooling different parts of the building at the same time. For example, in a high-rise living unit, the south-facing units may be in the cooling mode when the north-facing units are heating. Or in an office complex, the core may be cooling while the perimeter is heating. When some heat-pumps are heating the loop (in the cooling mode) and others are cooling the loop (heating mode) the loop temperature stays within acceptable operating range (60F to 90F) and the heat-pump system is at its most efficient – because heat is only being MOVED not created.

Buildings in northern climates that require mostly heating for long periods of time, will require a boiler to add supplemental heat to the loop. Buildings in southern climates that require mostly cooling will require a cooling tower and probably a mechanical chiller, to cool the loop. These types of buildings and locations do not get as much benefit from a heat-pump system. They still get the benefit of a highly zoned system that can do either heating or cooling with a simple switch in the thermostat, but much of the savings is lost when most of the heat comes from the boiler and most of the cooling comes from a mechanical chiller.

Because of the need to know building loads, zone needs, and equipment performance under different load conditions, a closed-loop heat-pump system is probably the most difficult system to design and install CORRECTLY. This type of system can operate in most any kind of building/application, but its higher installation cost must be carefully evaluated against its potential savings in operating costs. If heat can be moved around, then a savings will result. If most of the heat comes from a boiler, then the system ends up being an expensive distribution system.

See also Hybrid Heating Systems

Are geothermal heat pumps “greener” because they are better for the environment? Find out the facts inHeating System Emissions

Manufacturers and Organizations

For more information, visit the following web sites:

Geothermal Heat Pump Consortium www.geoexchange.org

Florida Heat Pump Manufacturing Company www.fhp-mfg.com

Bryant www.bryant.com

Lennox www.davelennox.com

Rheem (Rheem and Ruud) www.rheem.com

Trane Company www.trane.com/Residential/Products/HeatPumps.aspx

Waterfurnace www.waterfurnace.com

Weatherking www.weatherking.com

York International www.york.com