Flue Venting

Overview

All combustion appliances require air to burn the fuel and a method to get rid of the products of combustion. Improperly vented appliances cause many problems including:

- carbon monoxide production

- high moisture conditions

- fire potential

Some combustion appliances are designed to be “non-vented” which means they require no pipe to the outdoors, but they still vent, it’s just to the inside of the house. Non-vented appliances are limited to gas ranges and small space heaters and gas fire places.

NOTE: Most gas utilities do NOT endorse the use of non-vented space heaters and fire places, even if approved by local codes.

As appliances have become more energy efficient, the means to vent them has become easier. More heat is removed from the flue gases, allowing lower temperature materials to be used for vents. Many furnaces and water heaters can now be vented with plastic pipe.

All new appliances come with ‘Vent Tables’ that are suggested and code approved methods to vent the appliance. Be sure to follow all venting instructions provided by equipment manufacturers.

Operation

Vent Types

Type B Vent = double steel wall pipe used for most non-condensing furnaces and water heaters

Direct Vent = appliance vents through a wall (such as a gas fire place) with a vent provided by the appliance manufacturer

PVC Vent = low temperature venting system for condensing appliances

Masonry Chimneys

Masonry Chimneys

New energy efficient natural gas appliances should not be vented into older masonry chimneys without first determining the size, condition and whether or not the chimney is “lined”. Code will prohibit many instances of such use because of problems related to:

- energy efficient appliances do not produce enough waste heat to adequately heat a large masonry chimney; this means there could be poor or no draft produced

- flue gas condensation in an unlined chimney is corrosive to many masonry materials

- forced draft appliances may not have a fan large enough to move flue gases through a large chimney

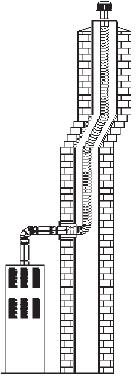

The least expensive way to retrofit a masonry chimney for new appliances is a continuous flexible metal pipe inserted into the chimney, sealed at the top, and connected directly to the appliance at the bottom. If the chimney also has structural issues, a more elaborate (and expensive) method inserts a long “balloon” inside the chimney and then special mortar or “grout” is injected between the insert and the inside of the chimney walls. The balloon insert is then removed, leaving a new right-sized masonry chimney inside of the old chimney.

The least expensive way to retrofit a masonry chimney for new appliances is a continuous flexible metal pipe inserted into the chimney, sealed at the top, and connected directly to the appliance at the bottom. If the chimney also has structural issues, a more elaborate (and expensive) method inserts a long “balloon” inside the chimney and then special mortar or “grout” is injected between the insert and the inside of the chimney walls. The balloon insert is then removed, leaving a new right-sized masonry chimney inside of the old chimney.

Sharing a Flue Vent

Up to two gas appliances, such as a water heater and furnace, can share a properly sized flue. If the furnace is a forced-draft model, the water heater must connect ABOVE (higher and closer to the vertical flue pipe) in an approved manner so that flue gasses go up the stack and not out the water heater draft hood. (See photo above)

Problem Venting

Problem Venting

There was a certain type of furnace design that included a section of the vent INSIDE of the return air plenum. This design has several problems:

- it is subject to an abnormally high amount of condensation because of cold air blowing directly across it

- holes in this pipe allows flue gases to be sucked out of the pipe and blown through the house by the furnace fan; therefore, even small holes can be responsible for large amounts of flue gas leakage

- it was NOT made of rust-resistant metal – ie: it easily rusts

Identify this type of furnace by:

- its size – they are quite large by modern furnace standards

- their age – at least 25 years old

- the burner and main heat exchanger are located in the front section, and the blower, filters and return air section are located in the rear section; this contributes to its large size

- the flue pipe exits the rear of the furnace, rather than the top

If this type of furnace is encountered in the field, be sure to remove the return air access panel, which is generally allowed to access the filters, and check the flue pipe for leaks. Use a mirror to especially carefully check the BOTTOM of the pipe as this is the most likely location of holes – which may be very small.

Even if the vent is fine, this age of furnace is a good candidate for replacement because of its relative low efficiency.

More Information

Manufacturers

Too many to list.

For an informative web site on metal flue liners see the Metal Fab site at www.mtlfab.com

Source: Text Bob Fegan 12/2008; photos Bob Fegan; flue graphics from the Simpson DuraVent catalog and Metal Fab web site;

© 2008 Energy Solutions Center400 N. Capitol Street NWWashington, DC 20001 All rights reserved. Legal Contact our webmaster