Food Service Equipment

Food Service

Applications

- Restaurants

- Schools and Institutional Food Service

- Hotels, Resorts, Convention Centers, Banquet Facilities

- Corporate Cafeterias, Office Parks, Military Installations

Overview

There are literally hundreds of types of commercial cooking equipment available, with thousands of options. Below is a sample of the most common gas equipment with typical specifications found at many commercial kitchens. This very abbreviated guide is meant to be only a primer; see the Cooking For Profit Catalog for a complete listing of available gas equipment.

Energy Efficiency

Cooking requires a certain amount of time and temperature to produce the perfect product. Energy Efficiency generally looks to reduce time and/or temperature to save energy. Not all products can be cooked faster with satisfactory results. While energy costs are important, it can’t compete with food quality. Therefore, energy efficient equipment is designed to cook faster and respond quicker to temperature changes – such as saving energy during a turn-down cycle – but is acceptable only where the food product quality will allow it.

Energy efficient equipment is designed with new types of burners that better mix the fuel and air for complete and hotter combustion. Radiant type burners direct the heat to where it is needed and away from non-cooking surfaces. Burners have multiple stages and controls to quickly react to temperature changes, so that they can save energy during off-cycles and quickly respond when needed, such as when a load of frozen fries are dumped into a fryer. Ovens have better door seals and insulation. Convection ovens use circulator fans to provide more even temperature. Combi ovens use steam to increase heat transfer, cook faster and retain more of the moisture.

Major Equipment Types

Gas Combi-Oven

Gas combination ovens are designed to create and deliver two of the most popular forms of commercial cooking heat transfer – pressureless (atmospheric) steam and forced convection hot air. These two primary cooking methods may be used separately or simultaneously. This means the combination oven gives you a choice of three basic cooking modes of operation.

Gas combination ovens are designed to create and deliver two of the most popular forms of commercial cooking heat transfer – pressureless (atmospheric) steam and forced convection hot air. These two primary cooking methods may be used separately or simultaneously. This means the combination oven gives you a choice of three basic cooking modes of operation.

This “triple threat” cooking capability has many advantages. First, since a gas combination oven may be able to do the work of two or more other types of equipment, you can save on the initial cost of kitchen equipment. Less equipment to buy can reduce ventilation hood space requirements and its cost. A single piece of equipment doing a multitude of cooking tasks can improve the efficiency of your entire production and service system while also saving labor cost.

Model 20 shown in picture is a floor-standing model with 170,000 BTU/hour rating.

Oven Proofer

The JAOP-14-G Combination Oven/Proofer offers high production in a compact, space-saving unit. The oven features a hot recycled reverse fan air system to assure even baking, reaching baking temperature in 15 minutes. The 60-minute reminder timer frees operator for other duties. Other standard features include steam injection system, full-view glass doors, all stainless steel interior and exterior. Proofer features adjustable shelving and automatic water system.

The JAOP-14-G Combination Oven/Proofer offers high production in a compact, space-saving unit. The oven features a hot recycled reverse fan air system to assure even baking, reaching baking temperature in 15 minutes. The 60-minute reminder timer frees operator for other duties. Other standard features include steam injection system, full-view glass doors, all stainless steel interior and exterior. Proofer features adjustable shelving and automatic water system.

- 73″ high, 68″ wide, 53″ deep

- 130,000 BTU

- Oven capacity: 14 – 18″ x 26″ pans

- Proofer capacity: 32 – 18″ x 26″ pans

Fryers

The super-efficient turbo jet MJH50 fryer uses up to 43 percent less energy to cook the same volume as conventional fryers. Frymaster’s unique 80,000 BTU/hr. (20,000 kcal) (84.4 megajoules) (23.4kW) turbo infrared burner produces like a 140,000 BTU (35,000 kcal) (147.7 megajoules) (41.0kW) unit turning out 80 lbs. (36 kg) of french fries per hour, frozen to done.

The super-efficient turbo jet MJH50 fryer uses up to 43 percent less energy to cook the same volume as conventional fryers. Frymaster’s unique 80,000 BTU/hr. (20,000 kcal) (84.4 megajoules) (23.4kW) turbo infrared burner produces like a 140,000 BTU (35,000 kcal) (147.7 megajoules) (41.0kW) unit turning out 80 lbs. (36 kg) of french fries per hour, frozen to done.

Solid State controls, electronic ignition, melt cycle and boil-out mode are all standard — along with the open-pot design and built-in reliability for which Frymaster is famous.

The MJH50 is available with a full range of options including basket lifters, computers and split pots to meet virtually all operational requirements.

This single, high efficiency (MJH50) gas fryer is shown with an optional built-in FootPrint® filter contained beneath it, combining high-volume, fuel economical frying with convenient, labor saving filtration for maximum, overall efficiency! No additional floor or storage space is required with this advanced automatic filtering system.

Rethermalizer

Specifically designed for reheating vacuum packed “cook-chill” foods, the FBR18 rethermalzing unit effectively heats meats, sauces, and other food at a safe temperature range that prevents overcooking. The preset temperature is adjustable with the solid state digital controller. The 1-1/4″ drain makes draining clog free. The timers are color-coded to correspond with the colors of baskets to simplify the preparation of various food products being warmed simultaneously. Large capacity baskets hold 2-5 pounds of vacuum bagged food each.

Specifically designed for reheating vacuum packed “cook-chill” foods, the FBR18 rethermalzing unit effectively heats meats, sauces, and other food at a safe temperature range that prevents overcooking. The preset temperature is adjustable with the solid state digital controller. The 1-1/4″ drain makes draining clog free. The timers are color-coded to correspond with the colors of baskets to simplify the preparation of various food products being warmed simultaneously. Large capacity baskets hold 2-5 pounds of vacuum bagged food each.

Features:

- 90,000 BTU/hr. (22,700 kcal) (94.9 megajoules) (26.4 kW)

- 22.5 gallon (85 litres) water capcity

- Jet infrared burners

- 6 corresponding color-coded baskets/knobs — eliminate confusion

- 18″ x 24″ cooking area (457mm x 610mm)

- Optional manual fill valve

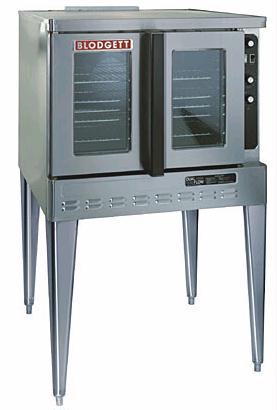

Convection Oven

STANDARD FEATURES

STANDARD FEATURES

- Stainless steel front, top, sides and back

- Solid state manual control

- Dual pane thermal glass window

- Porcelain door handle with simultaneous door operation

- Triple-mounted pressure door lock door design with turn buckle assembly

- Angle iron frame

- Double-sided porcelain baking compartment

- Interior lights

- Two-speed blower motor available 60 Hz only

- Modular slide out control panel

- 5 chrome-plated racks

- 11 rack positions

- 55,000 BTU per section

- Weight: 560 lbs/254 KG

Full-size Dual FlowTM Gas Convection Oven

The DFG-100 features the patented Dual FlowTM system, which makes the most of the heat in your oven by using it twice. Burners below the bake compartment heat the air that flows around its exterior, in turn heating liner walls and generating heat inside the oven. Then, a unique dual blower wheel pulls the hot air from outside the liner into the oven, mixing it with the hot air already present for excellent convection cooking.

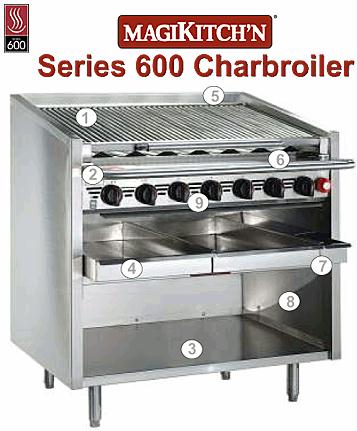

Charbroiler

Radiant or Coal Model?

Can’t decide between the convenience and low consumable costs of a radiant model or the great look of cooking over coals? MagiKitch’n solves this age old problem by providing an add on option of a coal rack that fits over the burners. With the new Series 600 you can even change from coal to radiant in the field with optional conversion kit. MagiCoal ceramics are conveniently placed on a stainless steel rack “coal” screen (shown below), eliminating the need for a firepot, cast iron burners, burner covers, and lower grates.

The Enhanced Series 600 line uses even more stainless steel unit, now comes standard with 6” service shelf with towel bar, and E-Z fill stainless steel water tubs. The Series 600 line is available as either a floor or counter top model in the following sizes: 24”, 30”, 36”, 48” 60” and 72”. All these models can be converted in the field to be coal (ceramic) models.

Free-floating top grid allows for expansion and contraction without warping. Removable grease box and crumb tray for easy cleaning. Charbroiler also operates as a range by adjusting top grid to a flat position.

- (1) Patented, E-Z tilt top grid controls grease and flare-up; when tilted 70% of the grease drains into a front trough.

- (2) Standard 6-inch deep stainless steel front service shelf.

- (3) Fully insulated lower storage area — standard on all floor models.

- (4) Water Tubs are a standard on our unit, not a cost adding option.

- (5) Seamless stainless inner sides and back for easy clean up.

- (6) Welded stainless steel drip trough directs grease into a box.

- (7) Grease box and water tubs are removable for easy cleaning.

- (8) Stainless steel outer panels over fully insulated double-walled outer construction to reduce side and bottom temperatures.

- (9) Two heat shields over manifold keep valves cool for long life.

Pasta Cooker

Gas or Electric. It’s not easy serving your customers pasta that’s cooked to perfection every time. If it’s cooked too long, it turns limp and soggy. If it’s not served immediately after cooking, it becomes cold and unappetizing.

Gas or Electric. It’s not easy serving your customers pasta that’s cooked to perfection every time. If it’s cooked too long, it turns limp and soggy. If it’s not served immediately after cooking, it becomes cold and unappetizing.

Now available in gas or electric models, Pasta Perfect can produce up to 500 ten-ounce servings of pasta every hour by cooking large quantities in advance, then warming individual orders as they’re received, so your customers don’t have to wait. And with automatic basket lifts and electronic time controls, every pasta dish is cooked perfectly — every time. Cooking and warming times from 5 seconds to 16 minutes give Pasta Perfect a range that covers virtually any pasta product — spaghetti, macaroni, noodles, ravioli, linguini, and vermicelli. And it does it all in less than seven square feet of floor space.

Key Features

- Complete self-contained work center requires less than seven feet of floor space.

- Cooking and warming times from 5 seconds to 16 minutes may be selected.

- Function selector switch determines mode, cook, or warm.

- Portion cup rack that holds up to nine individual portions cups.

- Cooking basket is lowered and raised automatically by electronic time control.

- Cooks approximately 15 pounds of pasta per load. Up to 190 ten-ounce servings of uncooked pasta per hour.

Deck Oven (Pizza Oven)

For a heavy-duty, high volume, fast recovery pizza oven, look no further than the Blodgett 1048 and 1060 ovens featuring bottom air intake. We have designed a system for transferring heat from the combustion chamber to the baking compartment, making them the most fuel-efficient ovens on the market today. The full width, dual spring door counter-balance allows for complete access to the deck. These ovens can be stacked to optimize your production capacity.

Key Features & Benefits:

Key Features & Benefits:

- Optional stone deck for hearth pizza or similar products.

- Steel decks are available for baking, cooking and roasting.

- Uses natural convection gentle airflow for delicate bake.

- Individually controlled sections for cooking various items at different temperatures.

- Minimal repair cost with simple, reliable controls.

- No electricity required for these gas ovens, reducing operating costs.

- Add-a-section designs allow you to start with one oven and add sections as your business grows.

- Battleship construction, walls, and frames are welded in a single unit for durability, providing you with years of cost effective operation.

- Counterbalanced doors provide ease of operation – less operator fatigue and injuries.

- Large, full-size door for easy access to cooking chamber.

- Large cooking area accommodates items.

MAXIMUM INPUT:

- 1048B single 120,000 BTU/hr

- 1048B double 240,000 BTU/hr

- 1048BL single 85,000 BTU/hr

- 1048BL double 170,000 BTU/hr

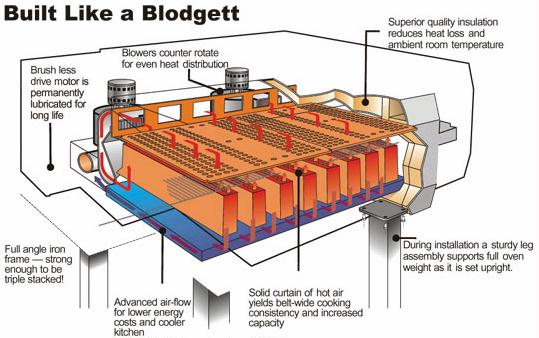

Conveyor Ovens

Blodgett makes Conveyor Ovens in a range of sizes to suit virtually every need. You can choose from space-saving compact floor units to large, high-volume models. No matter which one you prefer, all Blodgett Conveyor Ovens can be stacked — one, two, even three high.

Blodgett makes Conveyor Ovens in a range of sizes to suit virtually every need. You can choose from space-saving compact floor units to large, high-volume models. No matter which one you prefer, all Blodgett Conveyor Ovens can be stacked — one, two, even three high.

The Blodgett Conveyor Oven’s unique heating system provides consistent results and more cooking capacity. A solid curtain of hot air envelops the food as it moves through the cooking compartment, resulting in maximum heat transfer and more even results.

Similar principle as a convection oven, but improved because of directed airflow. As the heated air is forced over and under the product, it strips away the cold boundary layer and actually penetrates the product being cooked. As the product being cooked passes through the cook zone, the high and lows points of the product are cooked evenly because of this directed airflow.

Similar principle as a convection oven, but improved because of directed airflow. As the heated air is forced over and under the product, it strips away the cold boundary layer and actually penetrates the product being cooked. As the product being cooked passes through the cook zone, the high and lows points of the product are cooked evenly because of this directed airflow.

Plus, it delivers the heat where you want it — to the food — not to your kitchen. You get a cooler, quieter kitchen environment. Double insulation and advanced airflow engineering mean 70% of the heated air is recycled. Yet the oven runs more quietly than other conveyor ovens, and even quieter than most ventilation systems.

Key Features

- Simplifies cooking by automating cooking variables such as oven temperature and cook time.

- Labor savings — operators simply load and unload leaving hands-free time to perform other duties.

- Provides high volume and consistent cooking.

- Designed with large “Zone of Acceptability” for varying menu tolerance.

- Even Heat Distribution for belt-wide cooking.

Range

Features & Benefits:

Features & Benefits:

This unit is available in various top configurations please contact customer service to place order.

- Stainless steel front

- 6 each 30,000 BTU open burners

- 26″ oven 50,000 BTU

- Comes standard with 1 oven rack

- Oven thermostat adjusts from 150°F- 500°

- Oven controls located in cool zone

- Shut off device for oven and pilot burners in case of pilot outage

- Cast iron top grates

- Oven door to be spring balanced, mounted in self lubricating bearings

- 1 1/4″ front gas manifold

- 6″ adjustable legs

- AGA, NSF

Operating Costs

Operating costs are HIGHLY dependant on both the gross product through-put and the operator’s practices. There are a few ‘calculators’ that have been developed over the years (mostly by utilities) to compare gas and electric equipment. Primarily what they do is compare electric and gas BTUs on a cost per BTU basis; that’s the easy part. The hard part is to ACCURATELY determine a load profile.

For most equipment it’s a safe assumption to estimate a 50% load factor, based on name plate rating. Equipment that is operated for shorter periods of time will probably have a higher load factor, as the operator is shutting them off when not needed.

Input kW Rating x Run Hours x Load Factor x $/kWh = Operating Costs

To compare gas and electric equipment operating costs, assume the same input BTUs and the same Load Factor. It is reasonable to penalize the gas equipment by 20 – 30% for combustion efficiency, but the efficiency of getting the thermal BTUs into the food should be assumed the same.

100,000 BTUs – 25% Efficiency Factor = 75,000 BTUs

75,000 BTUs / 3,413 BTUs/kWh = 21.9 kWh per CCF of natural gas

Example: Compare a 25 kW Electric Deck Oven with a 125,000 BTU Gas Deck Oven

25 kW x 3,413 BTUs per kWh = 85,325 BTUs per hour

125,000 BTUs x 75% Efficiency = 93,750 BTUs

These are therefore pretty comparable pieces of equipment on a BTU basis

Electric = 25 kW x 50% Load Factor x 1 Hour x $0.12/kWh = $1.50 per hour to operate

Gas = 125,000 BTUs / 100,000 BTUs per CCF = 1.25 CCF

1.25 CCF x 50% Load Factor x 1 Hour x $1.10 per CCF = $0.69 per hour to operate

More Information

The Gas Foodservice Equipment Network’s goal is to help foodservice operators improve productivity, efficiency, and profitability. More than a million buildings in North America contain some type of commercial or institutional foodservice including restaurants, bars, fast food chains, cafeterias, hotels, motels, long term care, institutional operations, etc.Clean-burning natural gas-fired products offer commercial foodservice customers comfort, ambiance, and convenience. A variety of natural gas-fired appliances are used in today’s commercial kitchens. Over 100 manufacturers are producing more than 600 models of gas-fired kitchen appliances alone. An additional 100+ manufacturers produce natural gas fired technologies that are used outside of the kitchen for things such as HVAC, humidity control, water heating, power generation, gas lights/torches, patio heaters, fireplaces/fire pits and booster water heaters. This variety of gas-fired appliances and technologies offers a great opportunity foodservice operators to improve operations, save energy, improve customer comfort, etc.

GFEN is an organization of the Energy Solutions Center. Go to their web site at www.GFEN.com

Visit their web site at www.cookingforprofit.com

Manufacturers

BLODGETT

44 Lakeside Avenue

Burlington, VT 05401

Telephone: 802-860-3700, 800-331-5842www.blodgett.com

Note: Blodgett web site contains links and information on Pitco Fryers, MagiKich’n, Middleby Marshall, Toastmaster, and a couple others that are all part of the same corporation

Vulcan-Hart

2006 Northwestern Parkway

Louisville, KY 40203

Telephone: 800-814-2028www.vulcanhart.com