Energy Management Systems

Energy Management Systems and Controls

Introduction

A lot of what simple Energy Management Systems do can be done ‘the old fashioned way’ – manually. The primary advantage of an automated EMS is consistency and reliability. It also makes it possible for one ‘person’ to control multiple facilities from a central location via web based remote control. Alarms and failure notifications can be programmed to pagers, cell phones and e-mail, so that on-site monitoring can be reduced or eliminated. Advanced controls offer a range of control that is more sophisticated than is possible with basic manual ‘on/off’ switching. Demand limiting and shedding systems perform functions that would be very difficult to do manually. EMS can also be interfaced with building security systems, offering another level of integration and sophistication not possible with manual controls.

Early EMS were unique. It was necessary to stay with one manufacturer and one line in order for equipment to be able to communicate with each other. Today, most systems are cross-compatible or at least adaptable to work in almost any kind of environment. If components cannot be hard-wired to communicate, software and web-based systems can be made to work together. However, what may be possible may not be the least expensive or most proficient. Therefore, it is still best to choose a standard and stick with it.

Operation

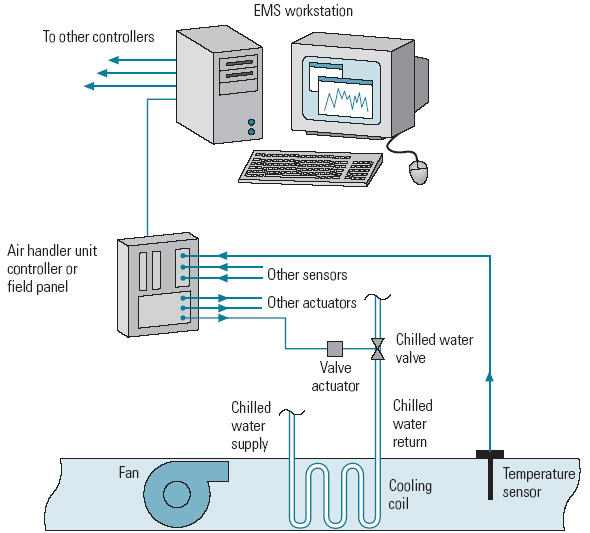

Basic temperature control EMS include thermostats, a central control panel, and interfaces to the HVAC equipment. A more advanced system that includes economizer controls will include a weather station to monitor outside temperature and optionally, humidity. Other outside sensors may include photo cells for lighting and daylighting controls. Basic programs are set according to ‘occupied and unoccupied’ settings. Systems will also include manual over-ride controls, which should reset to automatic after a short period of time.

|

|

|

|

|

EMS Weather Station |

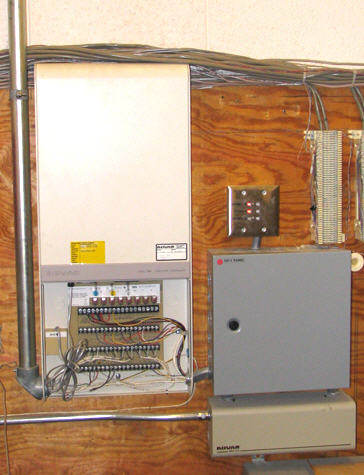

EMS Building Panel |

|

|

|

|

|

EMS Controller must be installed on each piece of equipment to be controlled

|

EMS Wall Stat

|

|

Systems that are designed to limit/control electric demand will include sensors on the main electric panel, and controls on each major source of controllable electric load – such as air conditioners.

Central EMS may also interface with other automated controls such as multiple air compressor controls and boiler controls. The air compressor controller may be monitoring multiple compressors to be sure there is adequate air pressure produced the most efficiently, and the EMS may be given further control to limit demand. A boiler control panel may be monitoring steam pressure and cycling the boilers, and the EMS is tracking run hours and gas usage.

Systems set-up for remote operation must include access to a phone line or network interface that can communicate with the outside world via the web.

Older Systems

Early control systems used pneumatic, or air pressure to sense and control equipment. Many of these systems are still in use today, and may be interfaced with new digital controls. If well maintained, the pneumatic system can be reliable. The system must be free of air leaks and have no condensed water in the control lines, both common problems.

|

|

|

|

Pneumatic Control Panel |

Pneumatic Air Compressor |

Pneumatic damper actuator |

Wireless Control

A major part of the installation cost of EMS is the installation of the control wiring. The newest systems offer wireless control. Although the component price is higher, the installation cost is substantially reduced. As with all electronic technologies, equipment continues to get better for a lower cost.

Manufacturers

Andover Controls

One High Street

North Andover, MA 01845

Telephone: 978-470-0555Web site www.andovercontrols.com

Invensys North American Headquarters

33 Commercial Street

Foxboro, MA 02035

Telephone: 508-543-8750Web site www.invensys.com

Johnson Controls, Inc.

Milwaukee, WisconsinWeb site www.johnsoncontrols.com

Novar Controls Corporation

6060 Rockside Woods Blvd. Suite 400

Cleveland, OH 44131

Telephone: 800-348-1235Web site www.novarcontrols.com