Space Heating Equipment

Overview

What is the BEST method to heat a building? This question is similar to asking, ‘what is the best brand of vehicle to drive?’ However, there are some general principals that can guide a heating system selection that are mostly accepted by HVAC (Heating Ventilating and Air Conditioning) professionals. Unfortunately, for new buildings, more often the over-riding factor is FIRST COST. When heating energy costs increase, more attention is directed at the heating system. At some point, replacement becomes an economical option.

When selecting a new heating system, the critical factors are:

- what’s the application (what kind of space will be heated)

- how big is the system (multiple units, central system, etc.)

- first cost

- operating costs

If the ‘wrong’ kind of equipment is installed for the application, or the ‘right’ equipment is improperly sized or installed, dissatisfaction results. Building use is sometimes changed from the time the heating system was first installed; the system that may have been ‘right’ for the building originally, may no longer be the ‘best’ choice. Also, technology improvements, new controls and new equipment with higher efficiency can mean that there is a ‘better’ choice today – even if the old equipment is still operating.

When considering heating system replacement, it is important to first understand the types of systems available, their pros and cons for a specific application and then consider its operating costs versus the operating costs of the existing system.

Facilities that have HVAC equipment that was properly designed for the current application and it’s in reasonably good condition, should not expect a rapid payback on heating system replacement. On the other hand, facilities with old equipment and/or not designed for the current application could see a rapid payback on a heating system replacement measure.

Types of Space Heating Equipment

Space Heating Equipment is either Direct Fired (no heat exchanger or flue) or Indirect-Fired (it has a heat exchanger and a flue) and is grouped in the following categories:

Direct-Fired

Space Heaters (Industrial Blow Thru)

Make-Up-Air (Replacement Air)

Air Recirculation (Make-Up-Air with less than 100% outdoor air)

Indirect-Fired

Air Turnover Units

Radiant Systems

Space Heaters (Blow Thru)

Space Heaters (Blow Thru)

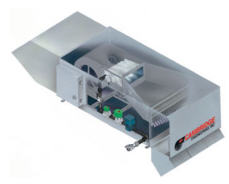

Blow-Thru, high efficiency space heaters are a popular choice for large warehouses, manufacturing plants and other types of commercial and industrial facilities. This direct-fired technology uses a ‘blow-thru’ gas burner/blower arrangement where the burner is downstream of the blower. This is important because it achieves the highest BTU/CFM ratio and allows this design be certified for the highest temperature-rise and outlet temperature rating of 160°F. The maximum temperature rating is crucial because it translates into lower horsepower motors, less outside air and reduced energy costs.

Indoor air quality (IAQ) can benefit because these systems do not recirculate potentially contaminated inside air. When properly applied, this design will neutralize the building’s natural air infiltration and heat the minimum volume of outside air. In very tight buildings, over pressurization may occur requiring use of relief vents. This heater type can be installed on the roof, under the roof, through the wall or pad mounted outside the building so it doesn’t consume valuable floor or vertical racking space and often has the lowest initial installed cost.

The induced rotating air effect created by the unit’s air velocity creates very effective air movement in the building, reducing stratification and temperature differences in the facility. Blow-thru space heaters operate intermittently and run at capacity only when required. They can offer the lowest total operating cost of any industrial heating system (gas and electric for blowers) and require very little maintenance.

For more information about Blow-Thru Space Heaters

Make Up Air

Draw-Thru Make Up Air (MUA) are also known as Replacement Air Systems. Their primary function is to heat large volumes of make-up or replacement air that have been lost from a space through either natural effects or power ventilation. MUA heaters are found in industrial buildings, restaurants, garages, auto service areas and maintenance facilities. They are often used in conjunction with other space heating equipment to solve negative air pressure problems (ventilation in excess of make-up air).

It is easy to confuse Draw-Thru MUA Heaters with Blow-Thru Space Heaters. Both are non-recirculating, direct-fired heating systems that use 100% outside air and look somewhat alike, however the technology inside is quite different. All MUA heaters use a “draw-thru” burner/blower configuration where the blower draws air through the burner. It moves a large volume of warm air through a low temperature-rise and provides constant CFM output.

Direct gas-fired Make Up Air units are the heating system of choice when large quantities of air need to be replaced during the heating season, such as where there is a lot of mechanical ventilation. They can be very expensive to operate as just a space heater however, because of the large volume of outdoor air they bring in even if the ventilation system is off. Optional VFD (Variable Frequency Drive) controls are a good choice to handle changing exhausted air requirements and will significantly lower electrical consumption and operating costs.

Most Make Up Air units do NOT have heat exchangers. The burners fire directly into the air that is used to heat the space. This is not an issue for spaces that turn over large volumes of air, but could be a concern to certain kinds of spaces without high ventilation rates. If the application requires it, indirect gas-fired MUA designs are available, but they are NOT as energy efficient as the direct-fired units.

For more information about Make Up Air

Air Recirculation Heaters

Air Recirculation Heaters

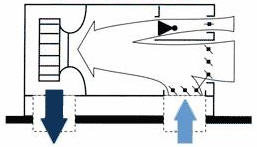

When properly applied, this draw-thru heater design can be used for both space heating and make-up air needs. The direct gas-fired burner heats a mixture of outside air and inside return air. It continuously modulates the ratio of outside air to return air to maintain a fixed positive static pressure condition inside the building. This is called pressurizing the building. The outside air percentage varies from 20% to 100%. It is often referred to as an “80/20” system meaning up to 80% recirculated inside air is mixed with at least 20% outside air. The best units will have variable air volume control with an adjustable mixed air damper controlled by air pressure and temperature.

Pressurizing a building is great for occupant comfort and is required to allow some processes/equipment to function correctly. However, EXCESS air increases energy usage. Gas consumption can be high for space heating applications for a leaky building, if there is excess ventilation or if dock doors are left open. When the building air pressure drops, the outdoor damper must open more and the volume of outdoor air can increase to 100%. Electrical consumption is also a factor because the large blowers run continuously.

ANSI implemented a new, separate safety Standard Z83.18 during 2003 for this heater category because they re-heat inside air. The concern is that the use of a building may change over time. Reheating inside air with direct gas-fired burners may be acceptable for the original application but not appropriate when use of the facility changes. Canada will not approve the new ANSI standard for this equipment so recirculation heaters are not typically used in Canada.

For more information about Air Recirculation Heaters

Air Turnover Units

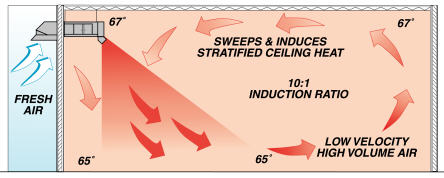

Air Turnover (aka: rotation) unit is the generic name given to large, typically floor mounted heating units. These indirect-fired units have heat exchangers and resemble large furnaces without ductwork. They have large fans that continuously turn the indoor air. It is typical to have only one or two of these units handle spaces as large as 100,000 sq.ft.

Air Turnover units work the best where ceilings are open/high (allow for circulation) and there is a limited amount of required ventilation. Such as warehouses, light assembly, indoor sports facilities and large retail stores. Some units optionally bring in a small amount of outdoor air (20%), which would allow them to maintain a positive air pressure in a building that does a small amount of power ventilation. Cooling coils can also be added for summer space cooling.

Because Air Turnover units have heat exchangers, their rated efficiency is lower than Space Heaters and Make Up Air units. This can make them more expensive to operate. On the other hand, where the total amount of outdoor replacement air is reduced, the operating cost can be reduced. Also,there are no issues about indoor air quality and temperature stratification/ uniformity is improved.

For more information about Air Turnover Units

Unit Heaters

The good ‘ol standard of industrial space heating is the hanging unit heater; everybody has them! They are available from stock, inexpensive to purchase, easy to install and maintain and they do a fair job of heating many applications.

Unit heaters work best in small buildings with low ceilings (less than 15 – 20 feet) and where there are not large quantities of power ventilation. Unit heaters have heat exchangers and passive flue systems. Unit heaters have small fans so they do not move much air; this tends to cause temperature variations (hot spots near and above heaters). Sometimes this is desirable for spot heating. In buildings with high ceilings, and heaters mounted high, the heat tends to stay high; they are often used with fans and other additional destratification systems in an effort to move the heat off the ceiling and down to the floor area. In buildings with negative air pressure (power ventilation in excess of make up air) unit heaters are prone to “back drafting” (flue gasses do not go OUT the vent as outdoor air is coming in; this causes condensation in the vent and heat exchanger of the unit heater leading to premature failure.)

Some unit heaters have been introduced that have double heat exchangers and power-flues. This can increase their efficiency by about 10%, but may double their first cost.

The highest efficiency unit heaters available are condensing models with rated efficiencies above 90%.

For more information on Unit Heaters

Furnaces / Rooftop HVAC

Many industrial and commercial spaces use common residential furnaces to heat offices and small zoned spaces within large plants.

Residential furnaces tend to be limited more by their fan size and thus cooling capacity, when used in non-residential applications. Most furnaces are only capable of handling up to 5 tons of cooling. These units will usually be smaller than 150,000 BTUs heating. They also do not have make up air capacity.

When larger cooling (and heating) capacity is needed and/or make air is needed, a rooftop mounted HVAC (Heating Ventilation and Air Conditioning) unit is the standard for medium sized buildings. If the roof is pitched or the building is multi-storied, the units will be located on ground pads, but their function is the same. HVAC units will have heating, cooling and some amount of make up air capacity all in one box.

For more information on Furnaces and Rooftop VAC

Boilers

Boilers have a very long, established history of providing steam and hot water for industrial process and space heating needs. Boilers are also the standard system for large commercial buildings with multiple zones, such as high rise buildings and multi-building applications such as school and hospital campuses.

Boilers are classified as Steam or Hot Water and steam is further classified as Low Pressure (15 psi or less), Medium Pressure (15 – 150 psi) and High Pressure (over 150 psi). Boiler types are identified as “Fire Tube” or “Water Tube”, the number of “passes” and other lesser factors and terms such as “wetback” and “Scotch Marine”. Smaller boilers are typically rated in Horse Power (HP) of thermal output capacity and larger boilers are typically rated in Pounds per Hour of steam production.

In some areas of the US and Canada boilers are facing tough new emissions regulations. NOx is the primary criteria pollutant being regulated from boilers. New retrofit low-NOx burners can be installed in boilers that are otherwise in good condition and sized for the application.

Old industrial facilities that no longer contain steam processes, or facilities that have converted to direct-fired or electric processes, often shut-down the central boiler in favor of one of the newer direct-fired space heating systems. Large boilers that operate on a very low load factor, and/or have suffered years of poor maintenance, are expensive sources of space heat. A new smaller boiler(s) and/or steam generator(s) sized to the actual process steam load along with a new gas-fired heating system can offer substantial savings.

Steam Generators

Boilers are different than Steam Generators in that boilers contain pressure vessels that store a certain capacity of thermal energy at all times; Steam Generators create steam with little or no steam storage capacity.

For more information about Boilers

Infrared Radiant Systems

Infrared Radiant Systems

Gas-fired Infrared Radiant space heating systems come in a variety of shapes, types and sizes. They all are designed for the same principle – heat the objects and not the air. A material such as the inside of a long tube or a ceramic grid is heated until it begins to emit infrared waves. The temperature and intensity (color and glow) are a function of the heater design and materials used. The waves travel in a line-of-sight direction until they strike an object causing it to become warmer.

Some outrageous claims have been made over the years by promoters of radiant heating systems regarding radiant’s savings over conventional systems. The bottom line is that heat loss (and thus heat cost) is a function of indoor temperature and size of the area. If a radiant system is properly sized and installed in the right application such that the indoor space temperature can be REDUCED as compared to a forced air system, then there is a potential savings. If a smaller space can be heated by spot-heating, then a savings should result.

Radiant systems work well in combination with Make Up Air and other central systems by spot heating people and/or materials to a higher temperature than what is provided to the rest of the space by the central system. Radiant heaters are also used outside, on loading docks, and for spaces like ice arenas where large temperature variations within the same space are desired.

Radiant heaters are also used in many industrial processes such as paper drying and plastic thermoforming. This section deals only with space heating applications and equipment.

For more information on Radiant Space Heating

More Information

Energy Efficiency

For information on Geothermal Heat Pumps and other Residential equipment, see the Residential section of this web site.