Radiant Hydronic Heat

Radiant Floor Heating

Radiant Floor Heating

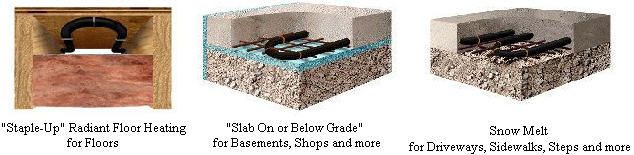

Radiant floor heating is rapidly gaining popularity in northern climates. Originally used mostly for commercial and multi-family applications (both indoor and outdoor see Snow Melt), radiant floor heating is enjoying a surge of use among high-end homes and those seeking a premium-comfort heating system.

Pros

- VERY comfortable for occupants

- warm, dry floors in cold climates

- easy to zone

- can use a combi-space /water heater

Cons

- high first cost

- not as effective under carpet and wood floors

- no duct work or fan that can be used for space cooling

Modern manufacturing techniques has made it possible to produce highly reliable (leak-resistant) tubing at an affordable price. However, boilers are more expensive than furnaces and the amount of tubing, valves and fittings required to make it work, results in a high material cost system. Installation requires a highly qualified expert for proper sizing and reliability.

Modern manufacturing techniques has made it possible to produce highly reliable (leak-resistant) tubing at an affordable price. However, boilers are more expensive than furnaces and the amount of tubing, valves and fittings required to make it work, results in a high material cost system. Installation requires a highly qualified expert for proper sizing and reliability.

Tubing can be installed in a variety of construction methods, but works best in masonry floors. Masonry floors transfer the heat easier and when unheated, tend to feel colder than wood floors so have the most to gain in comfort.

Tubing is installed so that all joints/fittings are accessible. A common header is plumbed inside of an access panel. Should an inaccessible pipe develop a leak in the future, it can be repaired or disconnected at the header.

Tubing is installed so that all joints/fittings are accessible. A common header is plumbed inside of an access panel. Should an inaccessible pipe develop a leak in the future, it can be repaired or disconnected at the header.

Zones can be created in an unlimited number of possibilities.

The tubing systems are designed according to:

- space heat loss

- available space

- the kind of floor construction

- diameter of the tubing

- water temperature

- tube spacing

Relatively low water temperature is used, which could improve boiler efficiency. If space comfort is improved such that a lower thermostat setting can be maintained, then energy savings could result. Otherwise, the same space at the same temperature using the same fuel at the same combustion efficiency is going to cost the same to heat regardless of how the BTUs are delivered to the space.

Baseboard Heating

Baseboard Heating

The baseboard radiator is the most common distribution system used with existing boilers. It uses only natural convection to move the heat from the water into the space. There are a variety of sizes and new designs to provide a range of BTU outputs to match most any design and aesthetic requirement. The general design steps are as follows:

- Calculate the space heat loss on a room by room basis

- Determine the available space for a radiator (lineal foot along outside walls)

- Select a radiator that will provide the required BTUs at the design boiler water temperature and fit within the available space

- Add up all individual room requirements to size the boiler

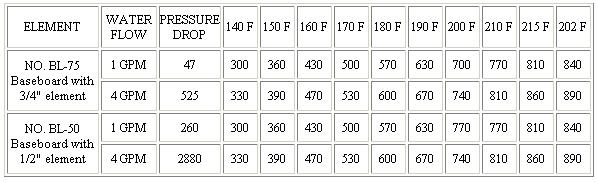

Typical ratings based on Slant/fin’s standard baseboard radiator with 65F entering air:

The above table shows the dramatic affect that water temperature has the capacity of a baseboard radiator. A typical system may be designed for 160F water. With a Boiler Reset Control (variable temperature aquastat – a devise that automatically controls the boiler water temperature according to a program based on outdoor temperature) the water can be run a little cooler during fall and spring, and a little hotter during the coldest parts of the winter.

Other Systems – Fan Coil

Other Systems – Fan Coil

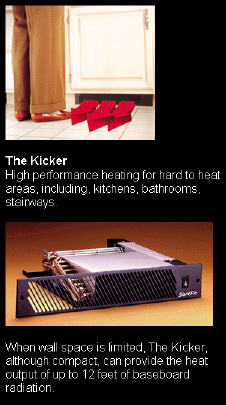

There are many specialty products designed to meet unusual aesthetic or space needs. Some of the more common equipment are fan coil units that use forced air to move the heat from the water into the space.

Fan coil units deliver more BTUs in a smaller space, but also require electricity to operate and generally require a higher water temperature to assure that the blowing air is not uncomfortable. They are also noisy, which eliminates one of the primary advantages of hydronic systems.

In some applications, the fan coil is the only way to get enough heat into the space because there just isn’t enough room for the length of convection radiator that would need to be used.

Fan coils can also be used in combination with cooling systems.

Another application is to bring in and heat fresh outdoor air before delivering it to the space. This type of fan coil is most typically found in commercial and multi-family applications.

More Information

Manufactures and Associations

The Hydronic Heating Association at http:// comfortableheat.net

There are many, many manufacturers of hydronic heating equipment. The ones shown here include those that have a national distribution network for a wide variety of both space heating and snow melting hydronic systems.

REHAU

Northeast Radiant

31 Hoyt Street, South Salem, New York 10590

Telephone: 914-763-3200

Slant/Fin

100 Forest Drive

Greenvale, NY 11548

Telephone: 516-484-2600

Watts Radiant

Springfield, MO

Telephone: 800-276-2419

Wirsbo

Apple Valley, Minnesota.

Source: Text Bob Fegan 12/2008; images from manufacturer’s web sites referenced and linked above;

© 2008 Energy Solutions Center400 N. Capitol Street NWWashington, DC 20001 All rights reserved. Legal Contact our webmaster