Flue Gas Heat Recovery

Introduction

Flue gas has a substantial amount of energy remaining in it after it has heated the process, but it can be difficult to recover for useful purposes. As a general rule of thumb, up to 20% of the input energy is lost in the flue gas, higher with process temperatures above 1,000F. If there is an application that could benefit from the use of hot water below 212F, then a condensing flue gas recovery system could be used. If the process is high temperature and there is a use for steam, then a Heat Recovery Steam Generator (HRSG – commonly pronounced ‘HeRSiG’) could be used. Units that spray water in direct contact with the flue gases are also able to be used as an emissions control technology. This is the same principal as a ‘Wet Electro-Static Precipitator’ (Wet ESP or Wet Scrubbers) commonly used for particulate emissions control. However, Wet ESPs typically don’t put the heated water to any other use.

Operation

The Specific Heat of Air is about 0.017 BTUs per Cubic Foot. Therefore, if cold water is to be heated by flue gas at 500F, then there is a potential to recover 459 BTUs per Hour from every cfm of flue exhaust air. The formula is:

(Flue Gas Temp) – (Water Temp) x (Specific Heat) x (60cfm to hour factor)

(500F Flue Gas – 50F cold water x 0.017 x 60cfm) = 459 BTUs per Hour

Flue gas also contains a large amount of water vapor. For every 1 pound of water condensed, 970 BTUs is given up. There is about 10 lbs of water vapor for every 1 Million BTUs combusted, or about 9,700 BTUs that could be recovered in condensate. Because flue gas is often hotter than 500F and cfm is generally measured in thousands of cfm, then the potential for energy recovery is huge. The heat recovery system may not recover 100% of the energy, but it is off-setting the energy that would have been provided by another system – such as a water heater or boiler, that is not 100% efficient either. When estimating the savings potential of a heat recovery system, be sure to consider the efficiency of the equipment that is/would be providing the heat if the recovery system were not in place. For example, 1 Million BTUs of recovered energy is actually worth 1.2 Million BTUs of purchase energy if the heating process is 80% efficient.

More Information

See Boiler Flue Gas Condensers and Economizers

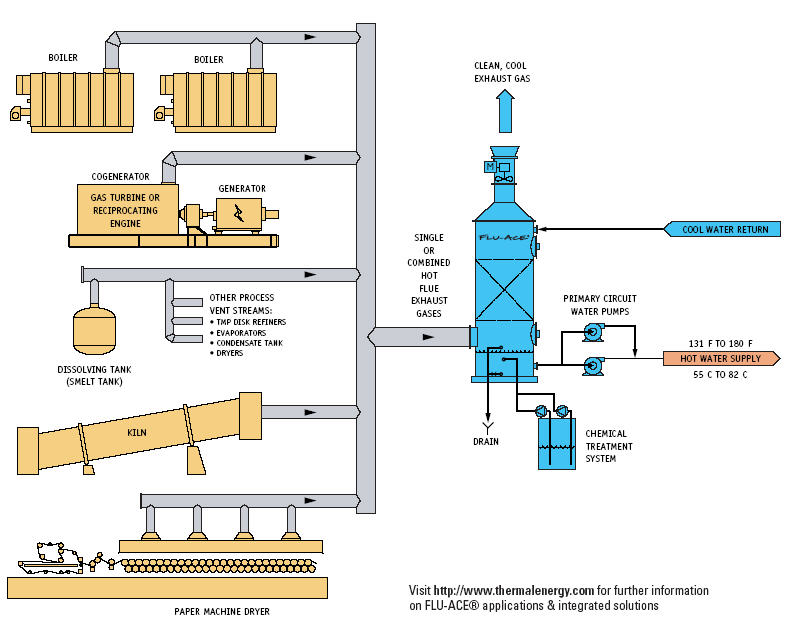

Power Generation Heat Recovery – Cogen/CHP, etc.

Manufacturers

Combustion & Energy Systems, Ltd 25 Royal Crest Court, Suite 110 Markham, Ontario L3R 9X4 Canada Telephone: 905-415-9400 Go to their web site at www.combustionandenergy.com Thermal Energy International Inc. Flue-Ace 36 Bentley Avenue Ottawa, Ontario, K2E 6T8 Canada Telephone: 613-723-6776 Go to their web site at www.thermalenergy.com Ludell Manufacturing Company 5200 W. State Street Milwaukee, WI 53208-2688 Telephone: 414-476-9934 Go to their web site: www.ludellmfg.com and www.elliscorp.com Source: Text Bob Fegan 1/2009; diagrams and images from manufacturer’s web sites referenced and linked above 3/2005; rev 8/2009;

© 2008 Energy Solutions Center400 N. Capitol Street NWWashington, DC 20001 All rights reserved. Legal Contact our webmaster